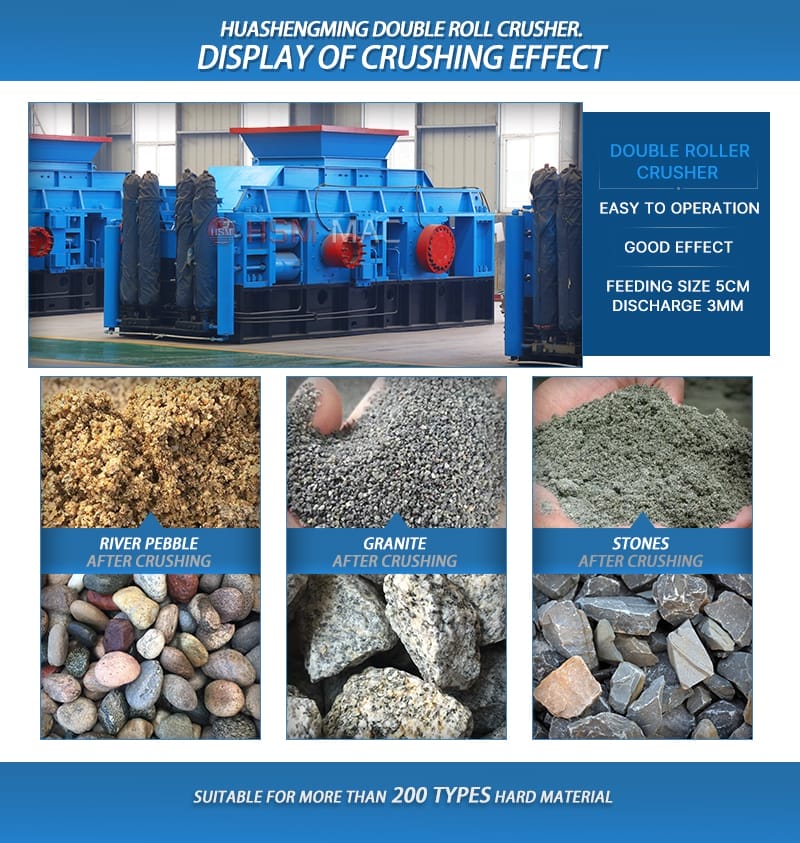

Roller Crusher

1. Gentle Yet Effective Processing

Our Roller Crusher provides the optimal balance between crushing efficiency and material preservation when processing soil. Unlike high-impact crushers that can pulverize clay particles, the controlled compression method maintains soil structure while achieving the necessary size reduction for your soil sand making machine.

2. Superior Moisture Management

Designed specifically for soil applications, our Roller Crusher handles materials with 15-30% moisture content without clogging. The counter-rotating rolls create a self-cleaning action that prevents material buildup, ensuring continuous operation in your soil sand making machine production line.

3. Energy-Efficient Operation

Compared to impact crushers, our Roller Crusher operates at 35% lower power consumption when processing soil materials. The efficient compression technology reduces energy costs while maintaining high throughput for your complete soil sand making machine system.

4. Consistent Particle Size Control

The adjustable roll gap allows precise control over final product specifications. This ensures uniform feed for your downstream soil sand making machine, optimizing its performance and producing consistently graded manufactured sand that meets construction standards.

5. Low Maintenance & High Durability

With fewer moving parts and specially coated rollers resistant to soil abrasion, our Roller Crusher requires minimal maintenance. The robust design withstands the variable characteristics of different soil types, providing reliable operation in your soil sand making machine processing plant.