The river pebbles sand making machine is purpose-built to turn river pebbles into high-quality construction aggregates—ideal for concrete, roadbeds, and building projects. Its core workflow, optimized for efficiency and consistent output, is as follows:

1. Feeding & Pre-Treatment (for River Pebbles Sand Making Machine)

First, belt conveyors move river pebbles to the machine’s feeding hopper. The adjustable baffle ensures steady feeding—learn more about conveyor systems on our equipment page. Surface impurities are cleared here to protect the machine’s components.

2. Primary Coarse Crushing

Next, the machine’s Jaw Crusher extrudes pebbles between fixed and movable jaws. Its durable liners handle river pebbles’ hardness, keeping the system stable.

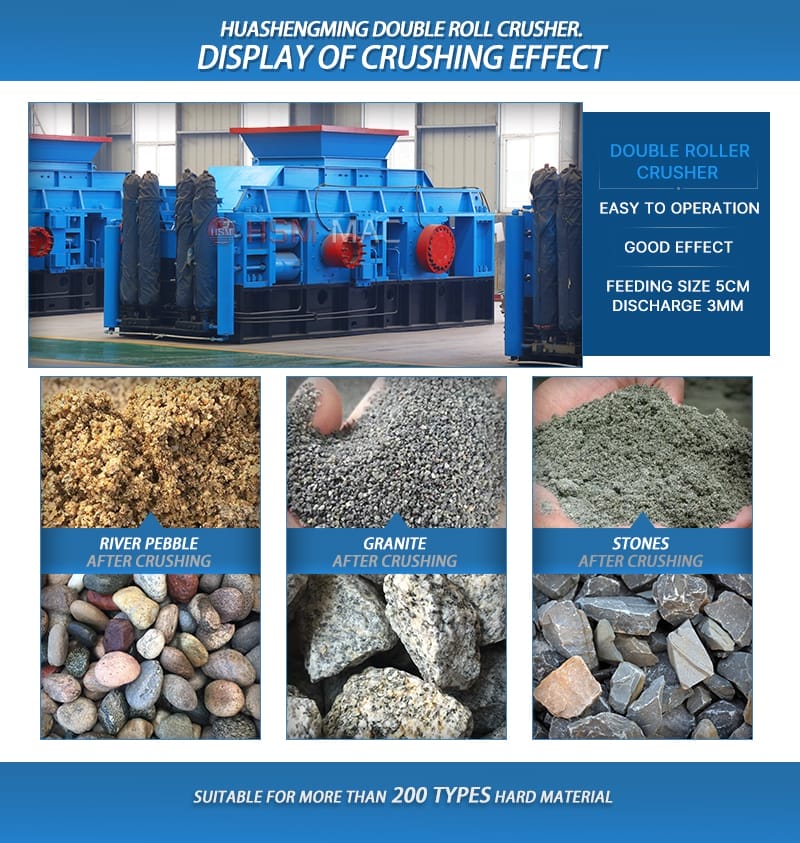

3. Secondary Fine Crushing

After coarse processing, aggregates go to the machine’s Roller Crusher. Its double-roll design produces uniform particles, with adjustable gaps for different project needs.

4. Screening & Classification

Then, the machine’s vibrating screen sorts materials by size. Unqualified particles loop back to the crusher, forming a closed production cycle.

5. Finished Product Handling

Finally, the machine’s dust removal system cleans aggregates (meeting environmental rules). Finished materials are stored in silos—these aggregates work for concrete, roadbeds, and more.