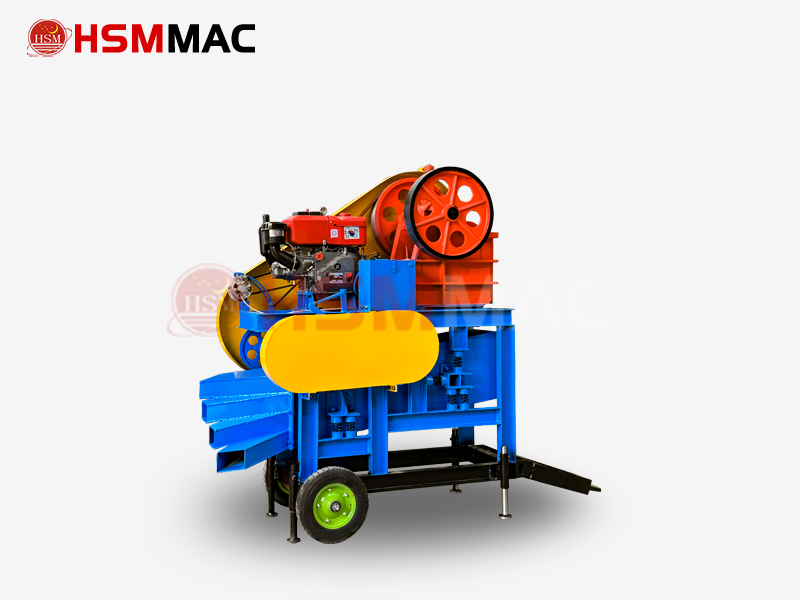

As a professional manufacturer of crushing equipment in China, Huashengming Heavy Industry is renowned for its small portable rock crushers, which are known for their high cost-effectiveness, durability, and flexible adaptability. These machines are particularly suitable for small and medium-sized mines, construction waste recycling, and temporary quarries. Below are the core product advantages, model selection, and purchasing guidelines:

small portable rock crushers for sale

1. Core Advantages: Technical Strength and Product Performance

Wear-resistant and durable design

Roll shell material: Made of high-chromium manganese steel alloy (containing rare metals), wear resistance is improved by 2-3 times, with a service life exceeding 8,000 hours, reducing replacement frequency.

No wear-prone components: Some models (such as hydraulic double-roll crushers) feature optimised designs that reduce traditional wear-prone components, lowering maintenance costs by 30%.

Precise particle size control

Hydraulic/mechanical adjustment of roller spacing (1–50 mm), uniform output particle size (1–5 mm fine sand or 30–100 mm coarse aggregate), cubic particle ratio >80%, and low over-crushing rate.

High efficiency and energy savings

Dual motor drive, with energy consumption as low as 0.5–0.8 kWh/tonne, achieving 30%–50% energy savings compared to impact crushers.

The intelligent hydraulic system automatically adjusts pressure to accommodate materials of varying hardness (e.g., limestone, shale, etc., with compressive strength ≤160 MPa).

Portable and flexible

Tyre-mounted/track-mounted chassis design, relocation time ≤ 2 hours, integrated crushing and screening functions, suitable for narrow construction sites.

2. Product series

Model classification Representative model Hourly output Price range Application scenarios Small spring model 2PGT400×250 2–20 tonnes Temporary quarries, Construction waste recycling Medium-sized hydraulic model 2PGY800×600 20–80 tonnes Small to medium-sized mines, processing of wet and sticky materials Intelligent tracked model 2PGY1000×800 50–100 tonnes High environmental requirements, frequent relocation

Note:

Small basic model (without screening function): Suitable for projects with limited budgets and hourly output ≤20 tonnes.

High-spec models: Includes hydraulic adjustment, pre-screening, metal detector, and supports remote monitoring (e.g., 2PGY2000×1200, hourly output 400 tonnes).

3. Application Scenarios and Performance Characteristics

Construction waste recycling: Crush concrete bricks and tiles → produce 0–50mm recycled aggregate with a utilization rate ≥90%.

Small and medium-sized mines: Process river pebbles, limestone, and other medium to low-hardness rocks, with an hourly output of 20–80 tonnes and precise, controllable particle size.

Wet and sticky materials: Supports clay and sandstone with moisture content ≤15%, featuring a shear anti-adhesion design to prevent blockages.

Environmental compliance: Closed structure + dust-proof panels, reducing dust by 60% and noise levels below 85dB.

4. After-sales service and support

Full-cycle service:

Free scheme design, trial operation with materials (on-site verification of production capacity at the factory).

Warranty period ≥ 1 year, spare parts supply ≤ 72 hours, nationwide service network coverage.

Technical support:

Smart control system training, remote fault diagnosis (next-generation models support AI predictive maintenance).

5. Purchase Recommendations and Pitfall Avoidance Guide

Selecting the Right Model Based on Requirements:

Material Hardness: For granite with hardness >150 MPa, select a jaw crusher + cone crusher combination; double-roll crushers are only suitable for medium to low hardness materials.

Mobility Frequency: For frequent site changes, select tracked models (e.g., 2PGY series); for fixed operations, select wheeled models.

Factory Inspection Focus:

Verify roller lining material (high-chromium alloy is superior to manganese steel) and test machine operational stability.

Contract Clarification: Warranty terms, spare parts supply timelines, and after-sales response speed.

Avoid pitfalls:

Direct purchase to save on price differences: Contact the manufacturer directly via the official website (e.g., hnhsm.com) or hotline (400-6596-395) to avoid agent markups.

Production capacity verification: Request third-party testing reports or visit case sites (thousands of successful cases nationwide).

Summary

HuaShengMing Heavy Industry’s small portable rock crushers feature wear-resistant durability, precise particle size control, and low energy consumption as core advantages, catering to diverse needs from temporary construction sites to medium-sized mines.

Cost-effective choice: The small spring-type model (2PGT series, starting at 14,000) is ideal for startup sand plants;

Smart high-spec recommendation: The medium-sized hydraulic tracked machine (2PGY800×600, around 150,000) balances production capacity and flexibility;

Act now: Contact the manufacturer (152-380-22995) to schedule a test run with your materials and verify the equipment’s suitability on-site.