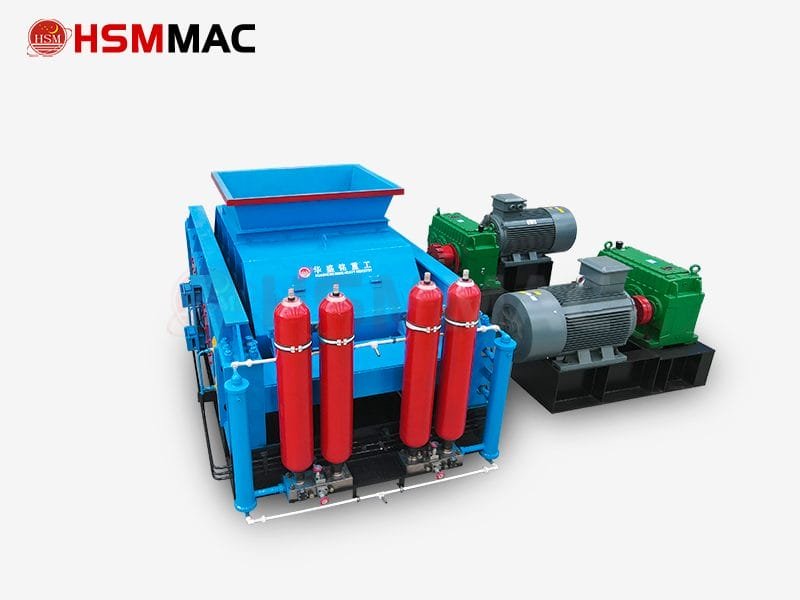

Huashengming offers roll crusher for sale.Roller crushers feature simple structure, controllable particle size, and low over-crushing rate as core advantages, making them particularly suitable for medium and fine crushing of medium to low hardness materials.

roll crusher for

1. Core Structure and Working Principle

Crushing Mechanism

Compression and Kneading: Materials are crushed through compression, kneading, and shearing forces between two counter-rotating rollers. This method is suitable for medium-to-low hardness brittle materials (e.g., limestone, coal gangue).

Particle Size Adjustment: Roll gap (1-50mm) is regulated via wedge devices or shim adjustments, achieving 95% uniformity in output particle size.

Overload Protection: Spring or hydraulic systems automatically retract the movable roll to prevent damage from hard objects (e.g., iron pieces entering the crushing chamber).

Core Components

Crushing Rollers: High-manganese steel or chromium alloy roller skins with over 2 years of wear resistance (30%-50% longer than standard materials).

Drive System: Dual motor drive + spur gear/V-belt transmission supporting differential rotation (enhanced anti-blocking capability).

Intelligent Control: Hydraulic models support remote monitoring and automatic gap adjustment (e.g., Huashengming hydraulic double-roll crushers).

2. Main Types and Technical Parameters

Classified by Roll Surface and Structure

| Type | Suitable Applications | Technical Features | Model |

| Smooth-faced rollers | Fine crushing of medium-hard materials (river pebbles, sandstone) | Primarily extrusion grinding with output particle size of 1-20mm and low over-grinding rate | 2PG-750×500 (15-40 tons per hour) |

| Toothed-faced rollers | High-moisture brittle materials (coal gangue, clay) | Combined splitting crushing and screening functions with anti-clogging design, maintaining stability at moisture content ≤15% | PCM Double-Tooth Roller Series (20-180 tons per hour) |

| Four-roller combination | Large-scale continuous sand production lines (capacity >100 tons/hour) | Two double-roll crushers connected in series with hydraulic synchronous control for precise particle size regulation | Custom Super-Large (300-450 tons per hour) |

Key Performance Parameters

| Model | Feed Size (mm) | Discharge Size (mm) | Capacity (t/h) | Motor Power (kW) | Reference Price |

| 2PG-400×250 | ≤25 | 1-8 | 5-10 | 11 | Starting at ¥18,000 |

| 2PG-750×500 | ≤40 | 2-20 | 15-40 | 37 | Starting at ¥22,500 |

| PCM-1600×1400 | ≤300 | Adjustable | 120-180 | 160+200 | Starting at ¥300,000 |

Notes:

Small-scale projects (<20 t/h): Select 2PG-400×250 for high cost-effectiveness and easy maintenance;

Medium-scale production lines: 2PG-750×500 balances efficiency and cost with wide adjustable output particle size range;

Large-scale sand making: Four-roller or hydraulic models (e.g., PCM series) support automation and offer lower long-term operational costs.

roll crusher for

3. Application Scenarios and Selection Recommendations

Preferred Scenarios

Wet/Sticky Materials: Toothed roller crushers (e.g., coal gangue, clay) with screenless design to prevent clogging.

Precision Sand Production: Hydraulic double-roll crushers (e.g., river pebble sand production) with controllable particle size down to 1-3mm.

High-Hardness Rock: Requires jaw crusher for primary crushing (e.g., granite), with double-roll crushers used only for secondary/tertiary crushing.

4. Core Operational & Maintenance Points

Standard Operating Procedures

Startup sequence: No-load startup → Reach rated speed → Uniform feeding (reverse sequence for shutdown).

Blockage prevention: Shut down to clear obstructions; never probe material during operation.

Maintenance Focus

Roll Shell Maintenance: Regularly inspect wear (uneven wear causes finer output particle size), promptly replace high-chromium manganese steel roll shells.

Lubrication System: Bearings use calcium-based grease, replenish weekly; gearbox lubricant replaced periodically (summer/winter formulations differ).

Spring Safety Device: Monthly elasticity checks; immediately replace if overload protection fails.

5. Huashengming Product Advantages

Wear Resistance Upgrade: Patented roll shells extend lifespan by 30%-50% while reducing maintenance costs by 50%.

Energy Efficiency: 30%-45% lower energy consumption per unit compared to traditional equipment (e.g., PDG-II double-roll mill boosts system output by 30%-40%).

Smart Service: Complimentary solution design + lifetime technical support