stone crusher machine Is it good to choose roll crusher? Whether the roller crusher is ‘good for use’ in the field of stone crushing needs to be combined with its performance characteristics, applicable scenarios and user needs to make a comprehensive judgement. The following four aspects are analysed from the core advantages, applicability, limitations and selection suggestions:

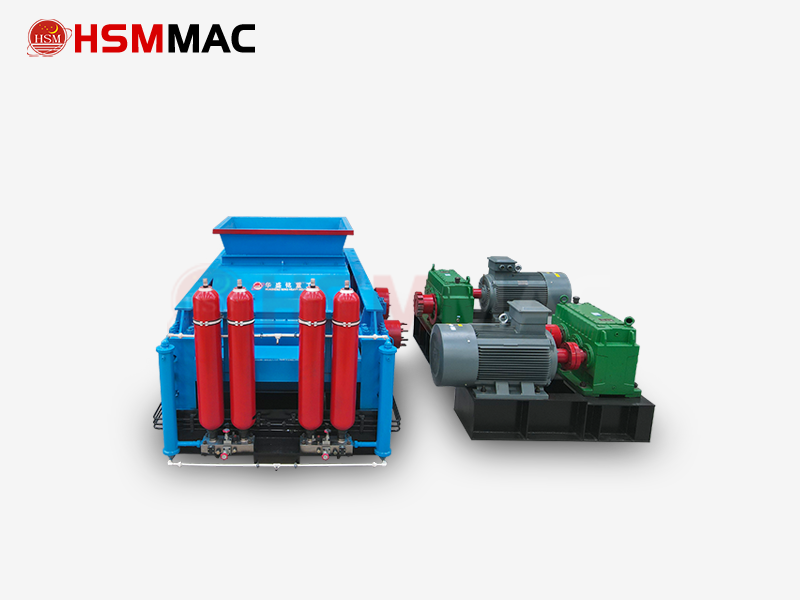

stone crusher machine roller crusher

1. Core advantages: why is it ‘good for use’?

High efficiency and energy saving

Low energy consumption: the double-roll crushing principle saves 30%-50% energy compared with impact equipment (such as hammer breakers), significantly reducing long-term operating costs.

Continuous production: high degree of automation, support 24-hour continuous operation, single machine processing capacity of up to 100-500 tonnes / hour, suitable for large-scale sand and gravel production line.

Precise and controllable particle size

Hydraulic or mechanical adjustment of the roller gap (usually 0-40mm, fine crushing can be up to 0.5-5mm), uniformity of the output material, low over-crushing rate, the finished product particle size rules, reducing the burden of subsequent screening.

Example: When the construction aggregate needs 1-5mm fine sand, the roller machine can directly produce qualified products.

Easy and durable maintenance

Simple structure, low failure rate (annual failure rate <5%), wearing parts only rollers need to be replaced regularly (wear-resistant alloy steel rollers can last up to 3 years).

Hydraulic overload protection can automatically remove iron, wet material and other foreign objects, reducing the risk of jamming.

Environmental adaptability

Closed design with dust removal system, the dust emission is lower than the national standard; the noise is more than 30% lower than that of impact breakers, which is suitable for environmental protection strict control area.

Both dry and wet materials can be processed, and it can still operate stably in rainy season or high humidity working condition.

roller crusher

2. Application Scenarios: Which situations are ‘especially good’?

Medium-hard and below material crushing

Ideal materials: limestone, pebbles, sandstone, gangue and other medium-hard materials (Mohs hardness ≤ 7).

Hard rock processing: granite, basalt and other hard rocks need to choose a large hydraulic model (such as 2PG1200 × 800), but the roll skin wear will be accelerated.

Construction aggregate and mechanism sand production

The finished product is angular, which improves the strength of concrete and is suitable for high standard building materials (e.g. C60 concrete aggregate).

Construction waste recycling (concrete blocks, bricks and tiles) with excellent crushing effect and over crushing rate below 10%.

Small and medium-sized production line transformation

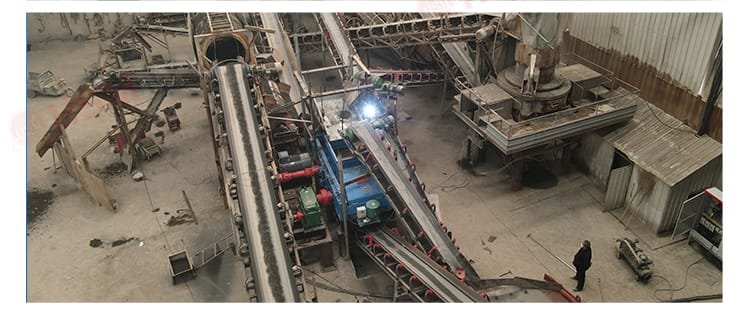

Modular design can be connected to the jaw crusher (after the coarse crusher) or replace the traditional sand making machine, easy to renovate the old plant.

Compact footprint (30% less space than cone crusher), suitable for sand and gravel plants with limited space.

roller crusher case

3. Limitations: when is it ‘not good enough’?

Low efficiency for ultra-hard materials

When crushing hard rock such as granite, roll surface wear increases, maintenance costs rise (frequent roll skin replacement), and unit energy consumption may be higher than that of a cone crusher.

Restricted feed size

Maximum feed size is usually ≤5cm, over-size needs to be pre-crushed (e.g. rough crushing with jaw breakers first), increasing the complexity of the process.

Dust and humidity sensitive

Toothed roll models are sensitive to dust, requiring additional dust removal inputs; high humidity may lead to roll sticking, requiring the installation of scrapers.

Roll crusher is a cost-effective choice for fine crushing of medium-hard materials, construction aggregate production, and high environmental protection requirements, with outstanding advantages of energy saving, controllable particle size, and convenient maintenance; however, in the case of ultra-hard rock crushing and large feed size requirements, it is necessary to carefully evaluate alternatives (e.g. cone crusher). Users are advised to match the model according to material characteristics, capacity and environmental requirements, and prioritise durable configurations and brand services to reduce long-term costs.