The mini crusher machine, also known as a double-roll crusher or double-roll sand maker, utilizes two motors to drive two sets of roll shafts to compress and grind materials. Designed for fine crushing operations with feed sizes under 80mm and finished product requirements ranging from 50 mesh to 20mm. Featuring roller shells made of high-chromium manganese steel containing rare metals, it achieves hourly production capacities of 5-400 tons, meeting diverse sand-making demands. Specifically engineered for crushing high-hardness materials like river pebbles, potassium feldspar, gravel, and quartz stone into sand. Featuring fully hydraulic automatic adjustment, adjustable discharge size, and capability for both dry and wet crushing. Widely adopted in quarries, sand plants, and sand production lines.

Mini Crusher Machine

1.mini crusher machine

Feed Size: 25-100mm

Production Capacity: 2-400 t/h

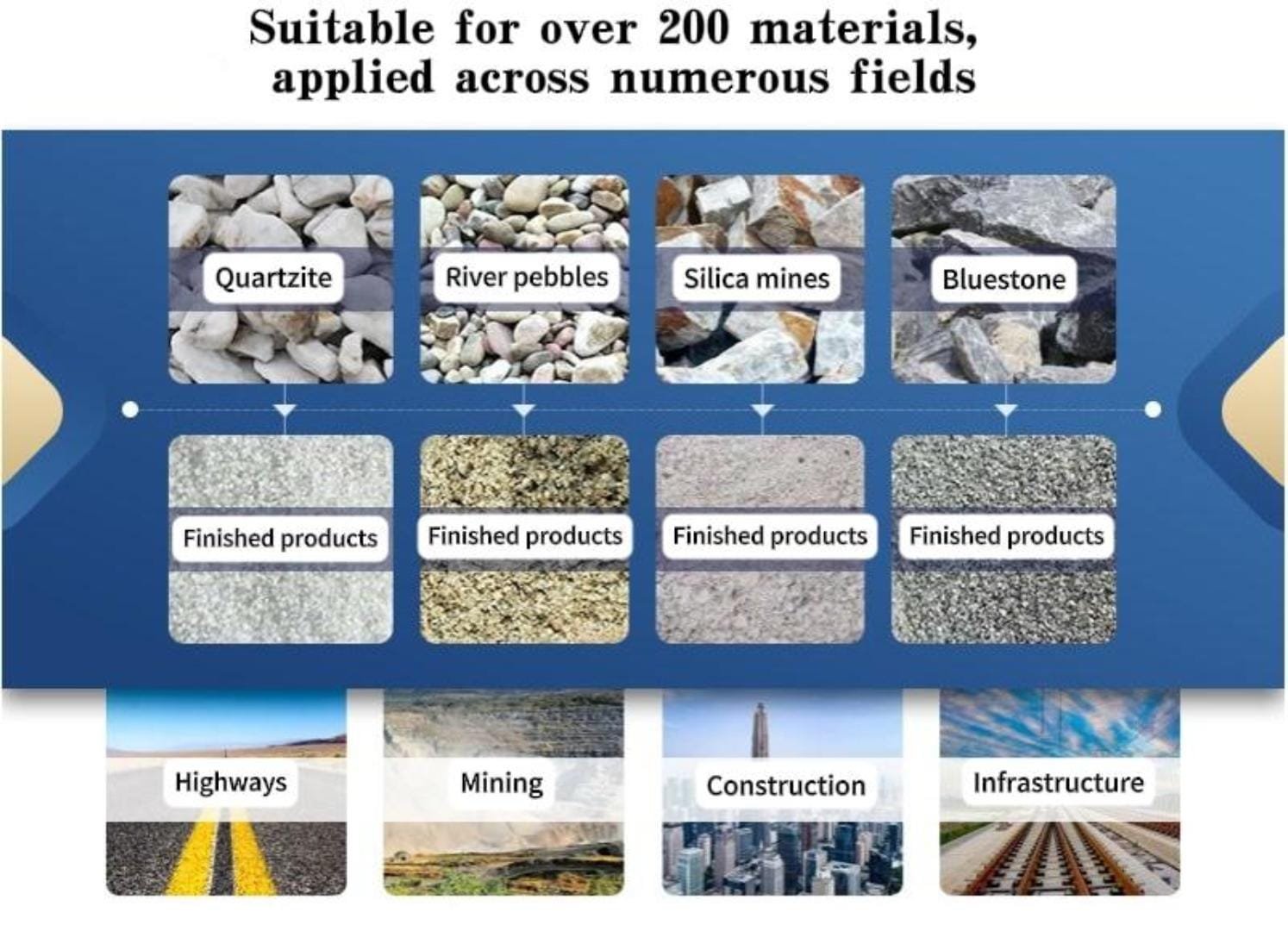

Suitable Materials:

River pebbles, calcite, quartzite, marble, cobblestones, bentonite, iron ore, bluestone, quarry rock, slag, limestone, weathered sand, diabase, granite, basalt, etc.

Application Scope:

Suitable for crushing in mining, cement, highway, railway, coal, metallurgy, building materials, and other industries.

2.Working Principle

The crushing operation is performed by rollers. Material enters between the rollers through the feed opening and is crushed by the squeezing action of the rollers. A specific gap exists between the two rollers. Increasing this gap results in larger discharge particle size, while the gap decreases under the force of compression springs, producing finer discharge particles. By adjusting the gap, the discharge particl

3.Performance Advantages

Simple and lightweight with powerful crushing force

High efficiency, low energy consumption, and superior output quality

Wide applicability and extended service life

Intelligent control for energy savings and labor reduction