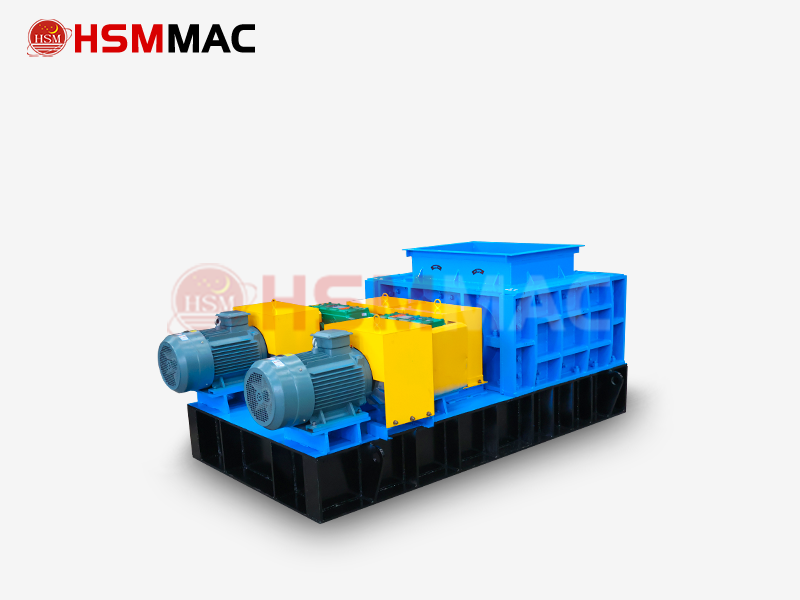

Huashengming sizer crusher(also known as Heavy-Duty Classifying Crusher or Double-Tooth Roller Crusher) is a high-efficiency device specifically designed for coal, metallurgy, mining, construction waste, and solid waste treatment sectors, combining crushing and screening functions.

sizer crusher

1. Core Technology and Performance Advantages

Crushing Principle

Dual-Roller Synergy: Two horizontally mounted toothed rollers rotate in opposite directions, utilizing impact shearing and tensile forces to fracture material along weak points. This reduces energy consumption and prevents over-crushing.

Synchronized Screening: Crushed material is discharged through gaps between rollers and comb plates on side walls. Qualified particles are rapidly separated, avoiding re-crushing and boosting output.

Intelligent & Safety Design

Overload Protection: Dual safeguards with hydraulic coupling + sensors prevent power overload.

Automated Control: Hydraulically adjustable tooth pitch, centralized bearing lubrication, and remote monitoring support.

Wear Resistance & Environmental Protection

Optimized Tooth Profile: High-chromium manganese steel plates/wolf-tooth design ensure >2-year lifespan with compressive strength ≤260MPa.

Low Pollution: Enclosed structure + dust removal system, noise ≤85dB, dust concentration <20mg/m³²⁶.

2. Main Models and Technical Parameters

| Model | Feed Size (mm) | Discharge Size (mm) | Capacity (t/h) | Power (kW) | Applications |

|---|---|---|---|---|---|

| 500-2000Series | ≤300 | 20–150 | 300–700 | 18.5×2(Dual Motor) | Medium-sized coal mines, construction waste processing |

| 625-2000Series | ≤500 | 20–240 | 300–800 | 110×2(Dual Motor) | Large coal preparation plants, solid waste recycling |

| 850-3000Series | ≤750 | 30–270 | 800–2200 | 160–220×2 | Mining primary crushing, large-scale sand and gravel production lines |

| 1500-3000Series | ≤1500 | 120–500 | 3000–5000 | 315–400×2 | Ultra-large metallurgical mines, aggregate production |

| SCF600×400 (Two-stagebreak) | ≤200 | ≤3(85%≤2mm) | 10–15 | 30–45 | High-moisture sticky materials (coal slurry, concrete blocks) |

3. Typical Application Scenarios and Effects

Construction Waste Recycling (Cangzhou Case)

Equipment: 2PGY750×500 (similar to 625-2000 model)

Results:

95% rebar recovery rate; aggregate (≤12mm) used for road subbase, reducing new material costs by 30%;

Comprehensive processing cost reduced to ¥60/ton (vs. ¥180/ton for landfill) 2.

Raw Coal Crushing in Coal Mines (Shanxi Case)

Equipment: 850-3000 model

Results:

Crushes raw coal containing gangue to 50mm, reducing over-crushing rate by 40% and increasing production capacity by 25%;

Hydraulic couplers minimize failure downtime, lowering annual maintenance costs by 15%.

High-Moisture Solid Waste Processing (Xinjiang Oilfield)

Equipment: SCF600×400 double-stage crusher

Results:

Clog-free crushing of 15% moisture content mudstone, output ≤3mm, 90% used for roadbed filling;

50m³/h output, saving 4 million yuan annually in purchased sand and gravel costs.