With its high efficiency, flexibility and durability, roll crusher is widely used in many industries. The following are the specific application scenarios and advantages analysed in each industry:

1. Mining and metallurgy industry

Hard rock crushing

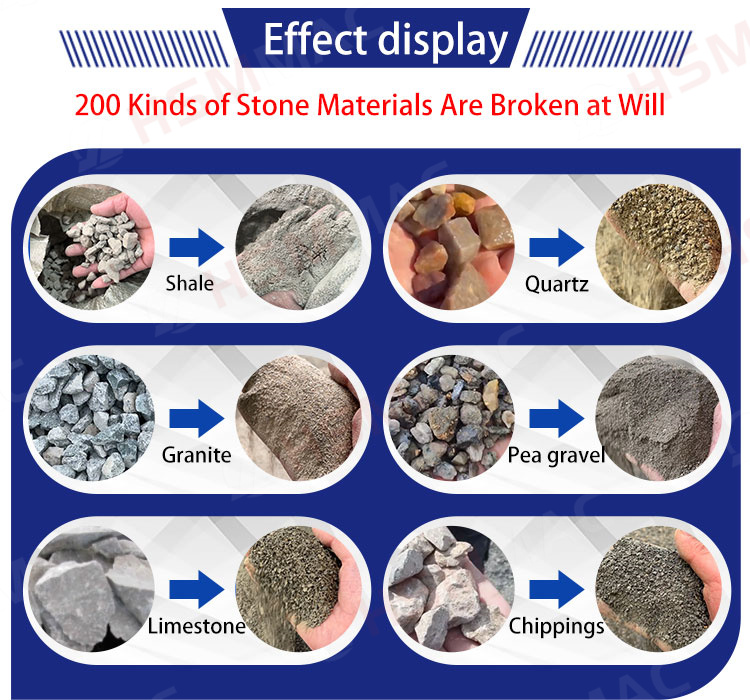

Application Scenario: Crushing granite, basalt (compressive strength ≥200MPa), iron ore and other high hardness minerals.

Advantage: The hydraulic system automatically adjusts the roll spacing to adapt to the change of material hardness; the roll surface is made of chrome-molybdenum alloy, which is highly wear-resistant and extends the service life by 2-3 times.

Case: Huashengming 1510 processing basalt, hourly output of 150-200 tonnes, the finished product size is uniform (1-5mm adjustable).

Soft mineral processing

Application Scenario: Fine crushing of coal, coal gangue, shale and other low and medium hardness minerals.

Advantage: flexible crushing to avoid over-crushing, precise particle size (0-15mm adjustable), suitable for the preparation of concrete aggregate or metallurgical raw materials.

2. Construction and building materials industry

Construction waste recycling

Application Scenario: Crushing concrete blocks, bricks and tiles and other construction waste, converting them into recycled aggregates.

Advantages: no screen bottom design to prevent clogging, wet material does not stick to the rollers (humidity ≤ 35%); discharge particle size ≤ 3mm, resource utilisation rate increased by 30%.

High quality mechanism sand production

Application Scenario: sand making from pebbles, lapis lazuli, limestone, used for construction mortar, decorative materials, etc.

Advantage: double-roller extrusion reduces needle-flake particles, and the finished product has full grain shape (cubic proportion ≥95%), which meets the requirements of high-standard building materials.

3. Highway and infrastructure projects

Roadbed stone processing

Application Scenario: Crushing basalt and granite to prepare road base aggregate (particle size 8-16mm).

Advantage: Intelligent overload protection automatically discharges metal impurities to ensure continuous production; energy consumption is as low as 0.8kWh/tonne, which is 20%-30% less than that of jaw breakers.

Asphalt Aggregate Preparation

Application scenario: quartzite, potassium feldspar and other hard rocks are crushed to 3-5mm fine sand for asphalt mixture.

Advantage: hydraulic precision particle control (error ≤ 3%), reduce over-crushing, and improve the compressive strength of the road surface.

4. Chemical and environmental protection industry

Chemical raw material processing

Application Scenario: Crushing fertiliser raw materials, sulphur and other brittle materials to provide particles that meet the process requirements.

Advantage: sealed design prevents dust leakage and avoids pollution; adjustable roller pressure avoids deterioration of chemical materials.

Solid Waste Resourcing

Application Scenario: Steel slag, industrial waste slag crushing and regeneration, used for filler or building materials.

Advantages: add anti-sticking scraper to deal with high humidity waste; dust emission <10mg/m³, noise ≤ 85dB, in line with green production standards.

5、Innovative applications in other industries

Ceramics industry: crushing kaolin and feldspar to micro-powder (≤0.1mm) to enhance the uniformity of blanks.

Power industry: fly ash re-crushing, optimise combustion efficiency.

Agricultural field: fine crushing of mineral fertiliser to improve soil improvement.