Huashengming Heavy Industry’s coarse crushers primarily encompass three major categories: jaw crushers, double-tooth roller crushers, and heavy hammer box crushers, catering to materials of varying hardness and production capacity requirements. The following outlines the core product types:

coarse crushers

1. Jaw Crusher (Coarse Crushing of High-Hardness Materials)

Core Features

Powerful Coarse Crushing: Utilizes high-strength jaw plates with feed size ≤125mm (e.g., PE150×250 model) and discharge size 10-40mm, ideal for primary crushing of high-hardness rocks like granite and basalt.

Simple and Durable Structure: Integral cast steel body for easy maintenance. 5.5kW motor delivers 5 tons/hour (5000kg/h) output at low investment cost (starting from ¥8800).

Mobile Option Available: Integrated tire chassis enables flexible relocation to mining sites or construction areas, reducing material transfer costs.

Typical Models and Parameters

| Model | Feed Size (mm) | Discharge Size (mm) | Capacity (t/h) | Applications |

|---|---|---|---|---|

| PE150×250 | ≤125 | 10-40 | 5 | Small-scale mining and building materials primary crushing |

| PE400×600 | ≤340 | 20-100 | 16-64 | Medium-scale sand and gravel aggregate production line |

2. Double-Tooth Roller Crusher (Specialized for Medium-Hard Brittle Materials)

Core Advantages

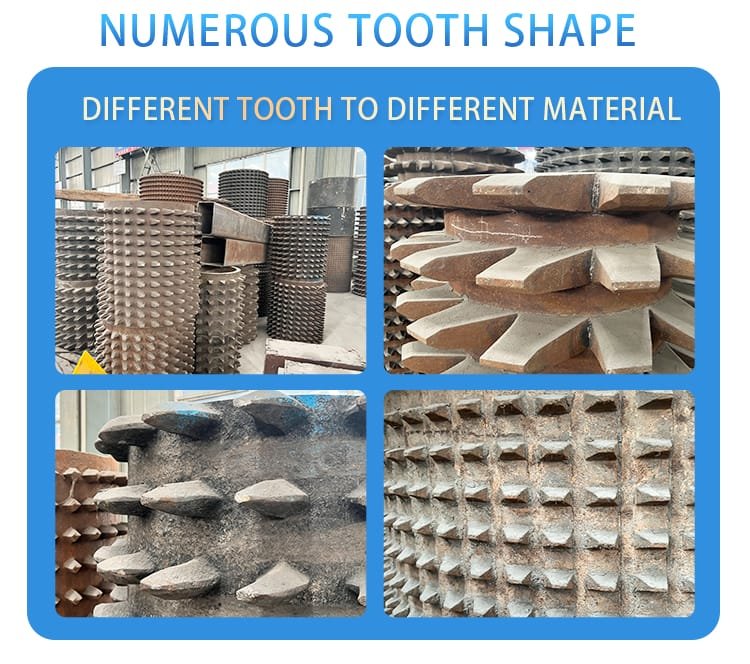

Gentle Crushing: Wolf-tooth/square-wave tooth design gently compresses materials (e.g., coal, coke), minimizing over-crushing (fineness rate <10%) while preserving aggregate integrity.

Wet Material Non-Blocking: Screenless bottom structure effortlessly processes coal gangue and asphalt millings with moisture content ≤35%.

Integrated Screening & Crushing: Modular design directly produces qualified particle sizes (adjustable 30-200mm), eliminating subsequent screening steps.

Main Models and Capacities

| Model | Feed Size (mm) | Discharge Size (mm) | Capacity (t/h) | Applications |

|---|---|---|---|---|

| 2PGC600×900 | 300-600 | 30-150 | 80-120 | Coarse crushing of coke and petroleum coke |

| 2PGC1200×1500 | 800-1050 | 30-200 | 200-300 | Large-scale mining intensive production |

coarse crusher

3. Heavy Hammer Square Box Crusher (Integrated Primary/Secondary Crushing)

Innovative Design

Two-stage crushing: Dual-rotor series configuration achieves primary + secondary crushing in one pass (e.g., granite → 20-50mm aggregate), simplifying workflow.

Energy-Efficient: 30% lower energy consumption per unit output compared to traditional lines. Integrated dust removal and noise reduction systems meet green mining standards.

Wear-Resistant & Long-Life: High-chromium alloy hammers + adjustable gap design extend lifespan by 2x, suitable for limestone, construction waste, etc.

Application Scenarios

Construction Waste Recycling: Concrete blocks → recycled aggregate (10-30mm), 90% utilization rate.

Hard Rock Crushing: Primary crushing of granite and basalt, achieving 400 tons per hour (large models).

4. Equipment Comparison

| Equipment Type | Optimal Applications | Suitable Materials | Representative Models |

| Jaw Crusher | Primary Crushing of High-Hardness Rock | Granite, basalt | PE400×600 |

| Double-Tooth Roller Crusher | Coarse Crushing of Wet, Sticky, Brittle Materials | Coal gangue, coke, asphalt | 2PGC900×1200 |

| Heavy Hammer Square Box Crusher | Integrated Coarse and Medium Crushing + High Environmental Requirements | Construction waste, limestone | Customize large models |