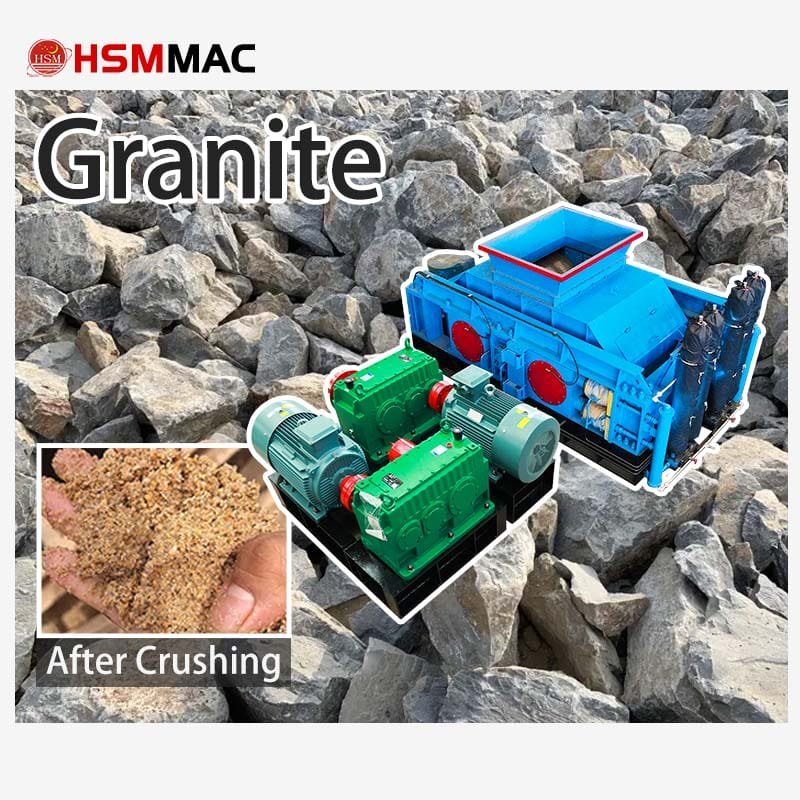

Granite as a high hardness rock (Mohs hardness 6-7), its sand making process requires high wear resistance, crushing efficiency and particle size control. So how about the effect of granite crushing and sand making with roll crusher?

High-precision particle size control and high-quality finished products

Uniform and controllable particle size: Through hydraulic or mechanical adjustment of the gap between the two rollers (adjustable from 0-5mm), the particle size of the discharged material can be precisely controlled, and the finished sand is full of grain shape, well-graded, with stable fineness modulus, which can satisfy the requirements of high standard of construction sand (e.g., concrete aggregate above C60).

Low over-crushing rate: the principle of extrusion crushing reduces the generation of stone powder (over-crushing rate <5%), which improves the proportion of high-value sand materials, and the rate of sand can reach 99%.

Wear resistance and equipment life of roll crusher

Strengthened wear-resistant parts: Roll crusher roll skin adopts 20cm thicker high chrome alloy or tungsten carbide liner, with hardness of HRC62 or above, which has a life span of up to 1-3 years when dealing with granite and reduces the frequency of replacement.

Overload protection design: spring or hydraulic safety device automatically backs off in case of hard objects to avoid equipment damage.

High efficiency, energy saving and high output

High crushing efficiency: Double rolls rotate in opposite direction to generate strong squeezing pressure, directly crushing granite, avoiding secondary crushing, and increasing output by 30% compared with traditional equipment.

Low energy consumption: with double motor configuration, the unit energy consumption is 15%-20% lower than impact sand making machine.

Environmental protection and low maintenance design

Closed dustproof: the sealing design of crushing chamber is matched with dust removal system, dust emission <20mg/m³, noise <80dB.

Automated operation: PLC control system realizes one-key start-stop and over-iron protection, which requires only 1 person to operate. The lubrication point is centrally arranged, and the maintenance cycle is extended to 1 time per week.

Roller sand making machine has become a cost-effective choice in granite sand making with the advantages of precise and controllable particle size, long wear-resistant life, low energy consumption, environmental protection and easy maintenance.