How To Choose Quartz Stone Sand Making Machine? Due to the high hardness of quartz stone (Moh’s 7) and strong abrasion resistance, the sand making equipment needs to take into account the crushing efficiency, finished product particle size and abrasion resistance. With its unique working principle and performance advantages, the roller sand making machine has become the ideal choice for quartz stone sand making.

1. Particle size control and finished product quality

Roller sand making machine will quartz sand can be precisely adjusted particle size, through the hydraulic system to adjust the double roller gap (usually 0.1-5mm). Can accurately control the discharge particle size (such as 1-5mm), the finished sand grain shape is mainly cubic, needle flake content of ≤ 15%, to meet the high standard requirements of construction sand.

Roller sand making machine adopts extrusion crushing method (non-impact type) to reduce the over-crushing rate and improve the effective sand output rate, especially suitable for photovoltaic sand which is sensitive to powder content (Fe₂O₃≤80ppm).

2. Crushing efficiency and energy consumption

High efficiency and energy saving

Compared with the traditional impact crusher, the roller machine relies on friction crushing. Energy consumption is reduced by 30%-45%, and the hourly output is 5-400 tonnes (e.g. 80-100 tonnes per hour for 2PGY1000×1000 model).

Strong continuous production capacity

The relative rotation design of double rollers supports continuous feeding. With intelligent control system automatically adjusting parameters. Reducing manual intervention and guaranteeing the stability of large-scale production (e.g., large hydraulic models up to 400 tonnes per hour).

3. Wear resistance and maintenance costs

Roller skin adopts thickened alloy (e.g. 20cm wear-resistant layer), life ≥ 800 hours. No need to replace within 3 years, reducing the frequency of downtime. Roller sand making machine has simple structure, quick replacement of wear parts (e.g. hydraulic cover opening design). And the maintenance cost is more than 40% lower than cone crusher.

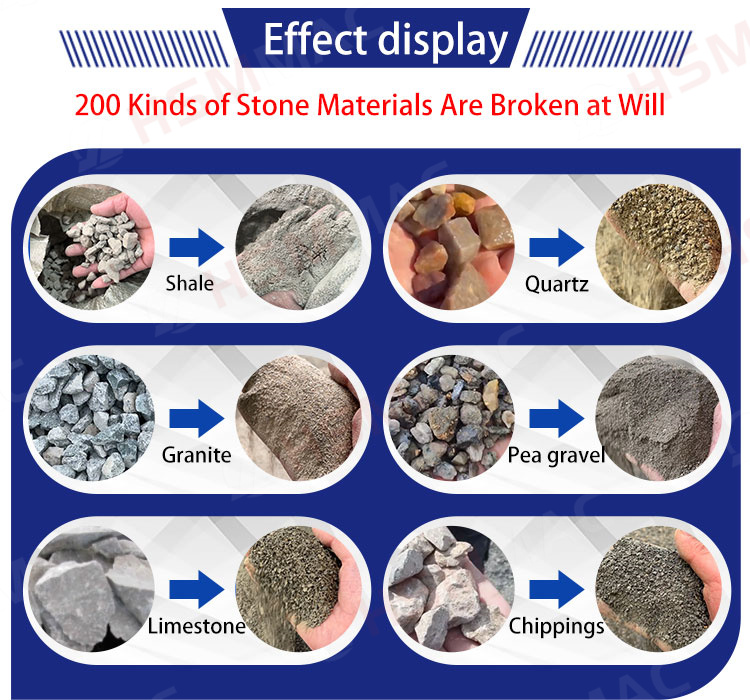

Roller sand making machine can also handle granite, basalt, construction waste and other hard materials, by adjusting the roller pressure to adapt to different hardness.

Roller sand making machine has the following features: controllable particle shape (cubic ≥ 90%). Low energy consumption (energy saving more than 30%). Strong wear resistance (long roller skin life); suitable for small and medium-sized to large-scale production lines. Especially suitable for production scenarios with high environmental protection requirements and the pursuit of long-term stability of quartz stone sand making.