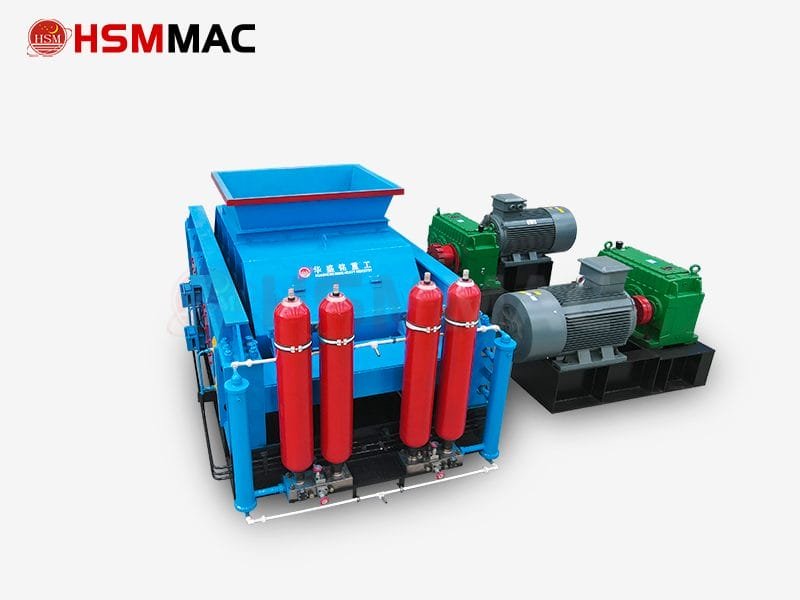

Huashengming Hydraulic Concrete Crusher is specifically designed for crushing construction waste (concrete blocks, bricks, tiles, etc.) and natural stone materials. Utilizing a dual-roller hydraulic compression principle, it controls output particle size (typically 1-50mm) by adjusting the roller gap (precision ±1mm), combining efficient crushing with resource recycling capabilities. Its core roll liners utilize a patented high-chromium manganese steel + rare metal alloy, delivering exceptional wear and pressure resistance with a lifespan exceeding 2 years, significantly reducing maintenance costs.

hydraulic concrete crusher

1. Core Advantages

High Efficiency & Energy Savings

The laminar crushing principle minimizes energy waste, achieving 20%-30% lower power consumption than traditional equipment; dual motor drive ensures stable power delivery.

Controllable Particle Shape

The hydraulic system precisely adjusts the roll gap, ensuring uniform output particle size (adjustable from 1-50mm). Needle and flake content is <10%, with low over-crushing rates, making the finished product suitable for concrete aggregate recycling.

Exceptional Durability

Patented roller skin material achieves HRC62 hardness, delivering impact resistance and high-temperature tolerance with a lifespan exceeding 2 years. Modular design enables rapid roller replacement, boosting maintenance efficiency by 50%.

Smart & Eco-Friendly

PLC control system supports remote monitoring and fault alerts. Enclosed structure + dust collection system ensures dust emissions <10mg/m³ and noise levels <75dB(A), meeting environmental standards.

Safety Protection

Hydraulic overload protection automatically retracts upon encountering hard objects, preventing equipment damage; spring-hydraulic integrated design enhances stability.

2. Application Scenarios

Construction Waste Recycling

Crushing concrete blocks, bricks, tiles, etc., producing 2-10mm recycled aggregate for roadbed filling or non-fired brick raw materials.

Natural Stone Processing

Processes river pebbles and granite (≤200MPa) to produce 1-3mm high-quality manufactured sand with rounded particles and optimal gradation.

Mobile Operations

Optional track/tire-mounted mobile stations enable flexible deployment at demolition sites or temporary quarries, achieving hourly output of 20-80 tons.