In mining, construction, or aggregate processing, crushers are essential for reducing large materials. Among them, three types are widely used: 3 Common Types of Crushers:Jaw Crusher, Impact Crusher, and Roll Crusher. Below is a concise breakdown of their workings and advantages.

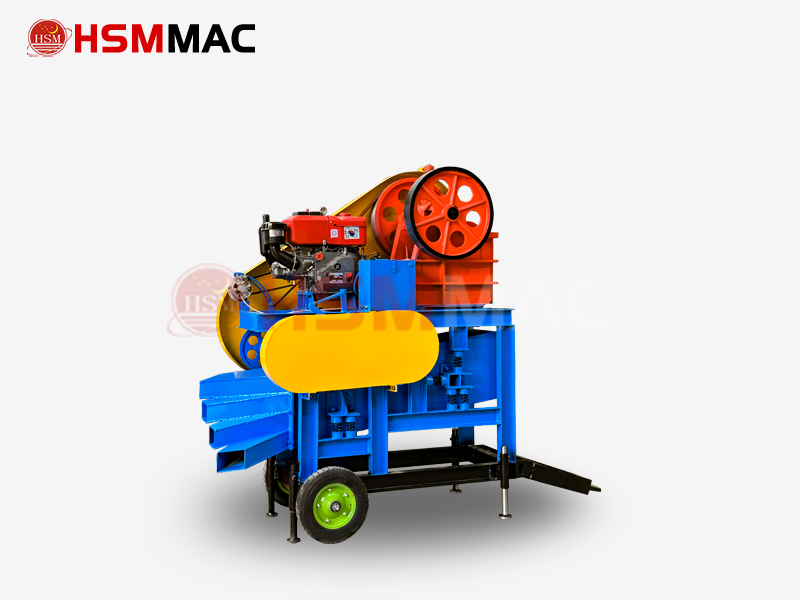

1. Jaw Crusher: The “Workhorse” of Primary Crushing

Mobile Jaw Crusher

The jaw crusher is a staple for primary crushing. It uses two jaw plates (fixed and movable) to squeeze materials via compressive force, handling hard materials like granite and iron ore effectively.

Key pros: Durable, low-maintenance, stable. Widely used in quarries and mines as the first crushing step for large boulders or raw materials.

2. Impact Crusher: For High-Quality, Cubical Products

Unlike jaw crushers, impact crushers use high-speed rotating blow bars to hit materials against impact plates, breaking them through impact force until they reach the desired size.

Its highlight: Produces cubical products ideal for concrete or asphalt. Efficient for medium-hard/brittle materials (limestone, coal) with adjustable output size. Not suitable for extremely hard/abrasive materials (wears blow bars fast).

3. Roll Crusher: The Gentle Giant for Fine Crushing

spring roll crusher

Roll crushers (often double-roll) use two inward-rotating rolls to crush materials via compression and shear, ensuring smooth, uniform fine crushing.

Suitable for soft-medium hard materials (coal, limestone, fertilizer) in secondary/tertiary crushing. Pros: Low noise, low dust, energy-efficient, simple structure. Cons: Lower capacity than jaw/impact crushers.

Quick Comparison

Jaw Crusher: Best for primary crushing of hard, large materials; durable and low-maintenance.

Impact Crusher: Ideal for producing cubical products; great for medium-hard, brittle materials.

Roll Crusher: Perfect for fine crushing of soft to medium-hard materials; low noise and dust.

Each crusher suits different needs based on material type, output size, and application. Understanding them helps make informed choices.

Got questions? Please Comment below! Follow us for more industry guides.