Roll crushers are essential equipment for fine crushing in industries like mining, coal processing and building materials. They deliver uniform particle sizes, low energy consumption and quiet operation, making them a preferred choice for soft to medium-hard materials. The market offers several specialized types of roll crushers, with hydraulic roll crushers, spring roll crushers and double-tooth roll crushers standing out as the most widely used options.

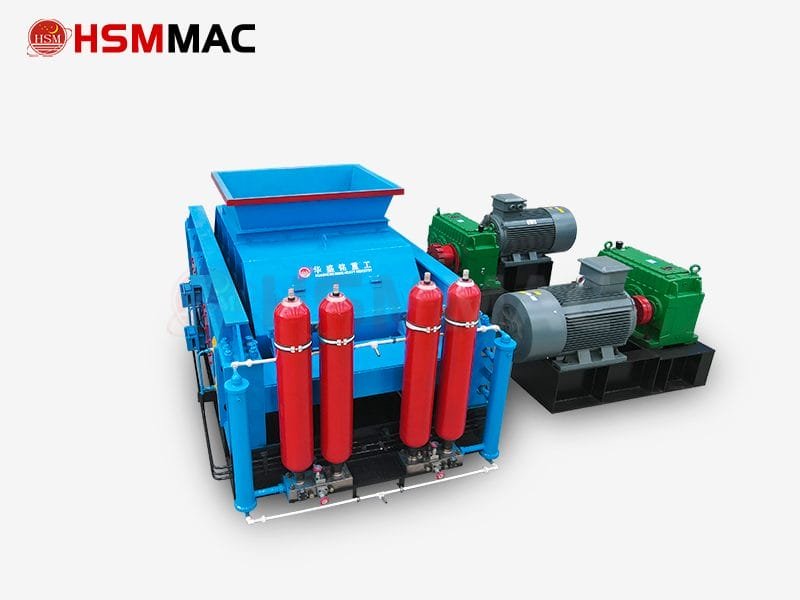

Hydraulic roll crushers combine advanced hydraulic systems with crushing mechanisms to deliver reliable performance. They use hydraulic cylinders to adjust the gap between rolls precisely, ensuring consistent product granularity. The hydraulic system also provides overload protection—when encountering uncrushable impurities, the rolls automatically move apart to avoid equipment damage, then reset to the original gap. These crushers suit high-demand scenarios such as limestone crushing and ore beneficiation, offering easy maintenance and long service life.

Hydraulic roll crushers

Spring roll crushers are classic models because of their simplicity and durability. They rely on spring assemblies to control the roll gap and absorb impact forces during operation. The spring system allows slight roll movement to handle material fluctuations, ensuring stable crushing efficiency. These crushers are cost-effective and easy to operate, making them ideal for small to medium-scale facilities like coal mines and gypsum processing plants. Their robust design withstands continuous operation, reducing downtime for repairs.

Spring roll crushers

Double-tooth roll crushers feature toothed surfaces on both counter-rotating rolls, specialized for crushing brittle and fibrous materials. The interlocking teeth grab and shear materials effectively, avoiding slipping and improving crushing efficiency. They excel in processing materials like coal, coke and biomass, producing uniform particles with minimal fines. These crushers are widely used in the coal industry and waste recycling sectors. And they handle sticky and heterogeneous materials better than smooth-roll alternatives.

Double-tooth roll crushers

Selecting the right type of roll crusher depends on material properties, desired output size and production scale. Invest in the appropriate model to enhance processing efficiency and reduce long-term operational costs.