Struggling with on-site crushing flexibility? Check out two top-rated mobile crushers for sale: mobile hydraulic roller crusher and mobile jaw crusher. Portable, efficient, and durable—ideal for quarries, construction, waste recycling, etc. Let’s explore their key features!

1. Mobile Hydraulic Roller Crusher: Precision & Stability for Fine Crushing

mobile hydraulic roller crusher

Tailored for fine, uniform crushing, this crusher features advanced hydraulic adjustment for precise discharge size. With tracked/wheeled mobile chassis, it moves easily on rough terrain, enabling on-site crushing and reducing transport costs—no complex foundations needed.

Key advantages:

Superior Hydraulic System: Stable, low-noise operation with overload protection to avoid damage and extend service life.

High Efficiency: Double-roller design handles limestone, coal, etc., with 10-100 TPH capacity for diverse needs.

Easy Maintenance: Wear-resistant alloy roller (replaceable) and simplified structure reduce downtime.

Ideal for: Sand-gravel lines, coal mining, building materials, and small-medium quarries needing fine crushing.

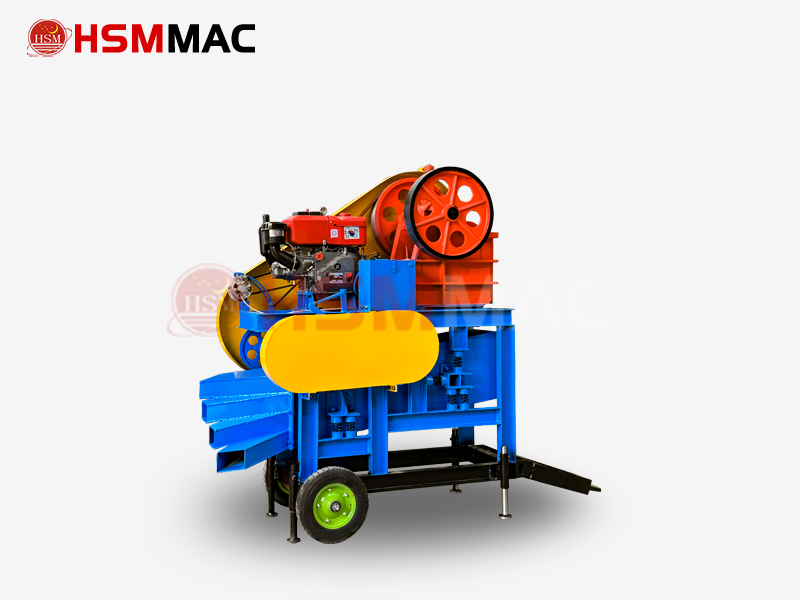

2. Mobile Jaw Crusher: Powerhouse for Primary Crushing

Mobile Jaw Crusher

The top choice for primary crushing of large, hard materials. With a large feed opening (handles up to 600mm bulk materials), it crushes granite, basalt, concrete effortlessly. Its mobile design enables quick site switching, saving time and labor.

Key highlights for heavy-duty use:

Strong Capacity: High-power motor and heavy eccentric shaft deliver 15-200 TPH, suitable for large projects.

Durable & Reliable: High-manganese steel jaw plate and reinforced frame ensure stability in harsh environments.

Flexible Configuration: Customizable with feeder, conveyor, dust remover for a complete mobile line.

Ideal for: Road-bridge construction, large quarries, demolition recycling, and hard material primary crushing.

How to Choose Between Them? Key Tips for You

Not sure which to choose? Here’s a quick guide:

Material: Jaw crusher for hard/large materials (primary); roller crusher for medium-soft/fine crushing (secondary/tertiary).

Output: Jaw crusher for >100 TPH primary crushing; roller crusher for small-medium fine crushing output.

Environment: Both suit outdoor/remote sites; tracked version preferred for muddy/uneven terrain.

Hot Sale! High-quality crushers at competitive prices. 1-year warranty + 24/7 after-sales. Standard or customized—free quote now!